Products

Gravity Racking System

Five Advantages Of Products

- Multiple heavy-duty roller options

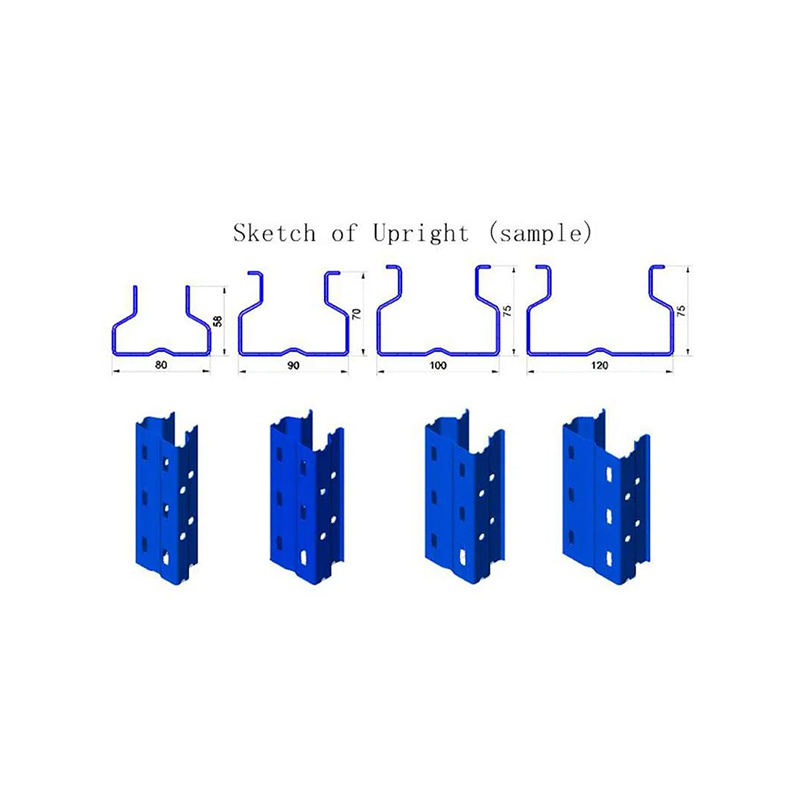

- Economical roll formed columns

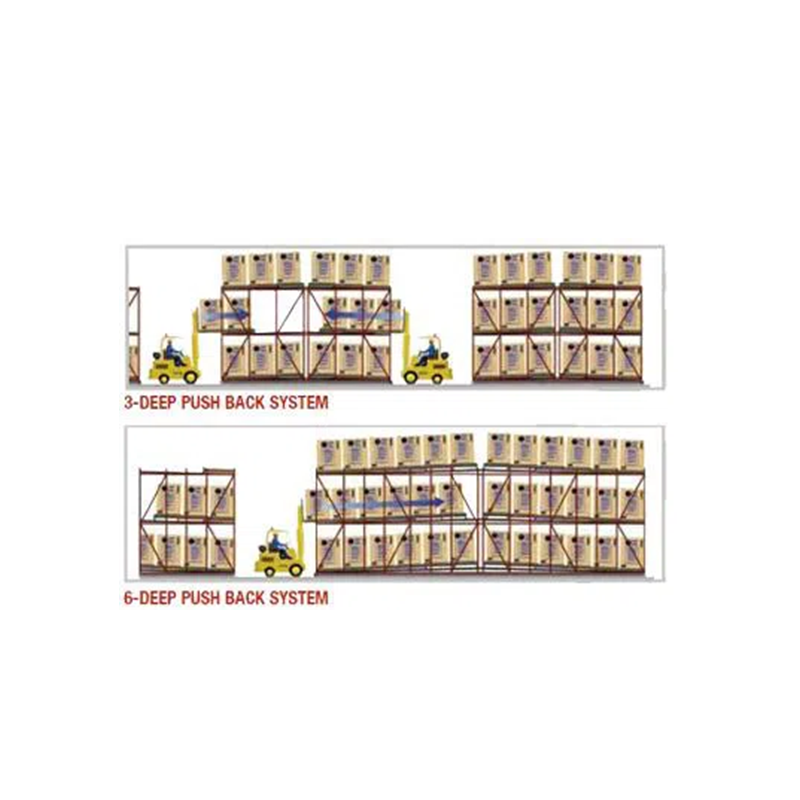

- Deeper systems

- Pallet flow audits and testing

- Available entry guides

Product Details

Product Details

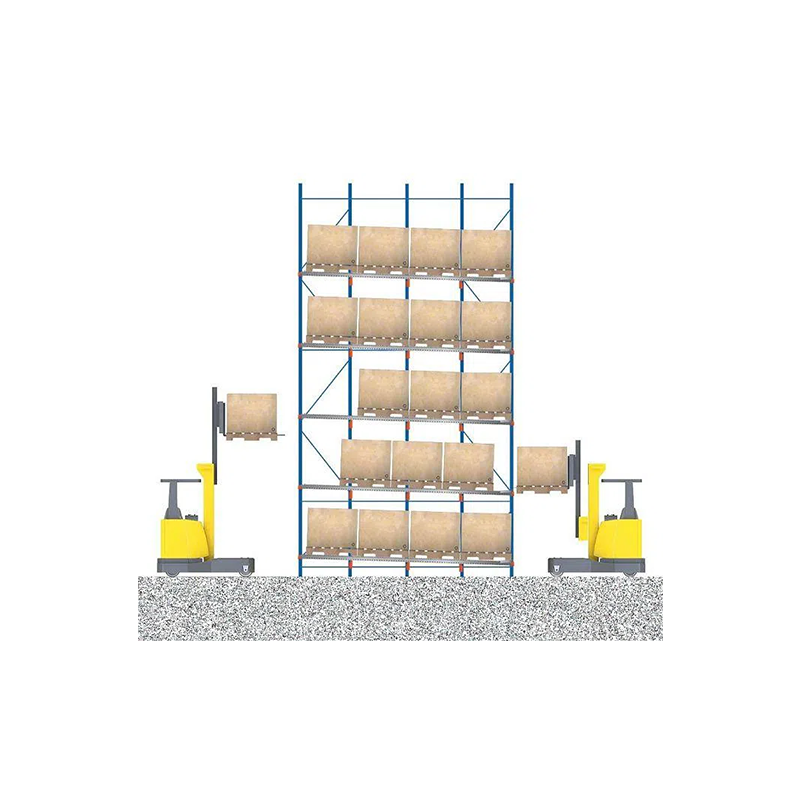

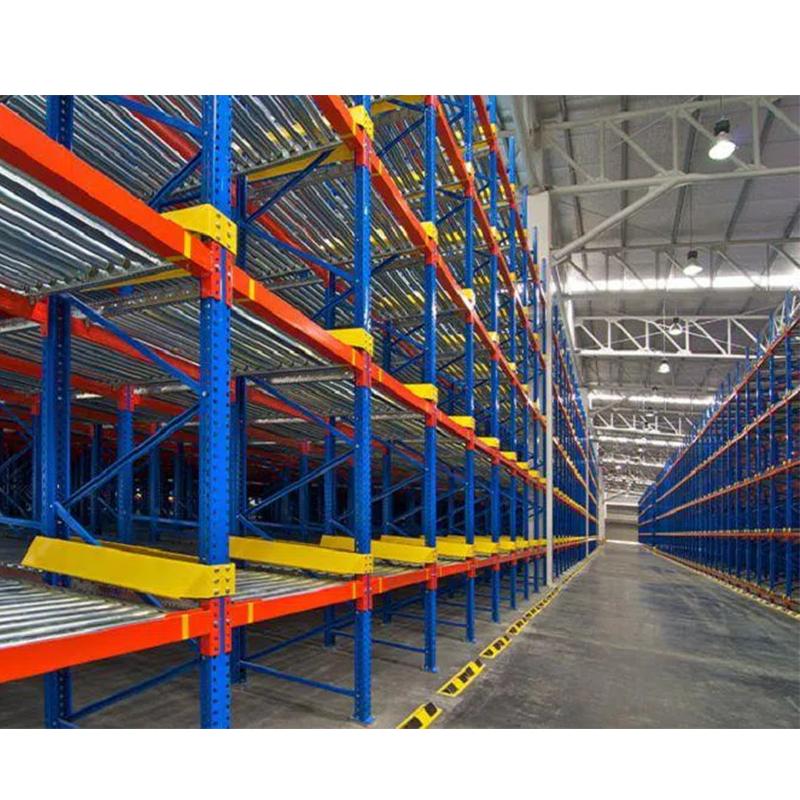

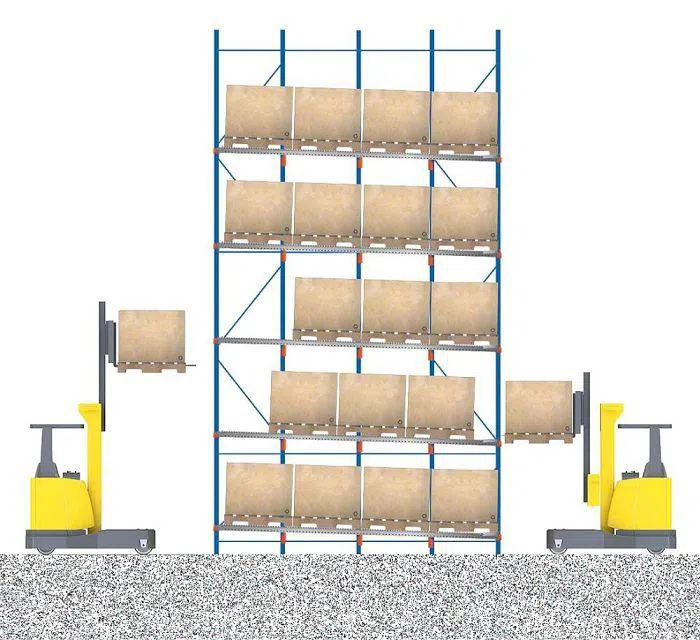

Gravity racking system is kind of FIFO deep storage system where the pallets are placed at one side (entrance side) of the racks and delivered to the other side by means of gravity rollers. When the operator takes a pallet from the exit side of the rack automatically the second pallet moves forward by the gravity rollers and stop at the end safely thank to the breaks, mechanical stoppers and pallet separators.

Gravity racking system is one the most cost effective storage solutions as it helps to utilize the warehouse because the system eliminates the picking aisles created by the conventional systems. It’s the perfect solutions for intermediate warehouses and buffering operations where a production line is feeding another production stage.

Gravity racking system is a high-density storage system that allows multiple pallets to be fed from warehouse load ends to pick ends. This First In, First Out (FIFO) rack can be adjusted to the desired depths to meet your capacity needs. Beams can be set on top of beams and can vary in height and provide a downward pitch. Utilizing pallet flow will help you ensure you are getting faster and more accurate pallet transfers in your facility.

Unlike the Drive in system the gravity racking system can store difference SKUs in the different levels at the same aisle which makes it a versatile system. Gravity racking system reduces the travel time by forklifts leading to productivity increase and decreasing energy consumption.

Features

●Multiple heavy-duty roller options

●Economical roll formed columns

●Deeper systems

●Pallet flow audits and testing

●Available entry guides

●First in – first out per lane

Applications

●Distribution centers

●Pick modules and staging areas

●Large value per SKU

●High throughput

Operations

Pallets are loaded into the storage lane from the loading aisle and gravity fed, in order, to the discharge aisle. The pallets are first placed onto rollers upon which the pallets easily flow towards the front of the rack system. Once they’ve glided to the front of the system, pallets rest on pallet stops until they’re unloaded. As pallets are removed or unloaded from the system, each of the pallets that were behind them “flow” into the next position via gravity. Pallet speed is controlled by the type of rollers and brakes engineered into the system.

Case

Jiangsu Welfor Storage Equipment Co., Ltd.

Contact Person: Casy Chen

Telephone: +86 13851406693

Landline: +86 025-52111679

Company Address: No.6 Tongkuang Road, Guli Industrial Development Zone, Jiangning District, Nanjing City, Jiangsu Province, China

Website: www.rackmanufacture.com

Previous: Gravity Racks For Pallets

Next: 4 Deep Push Back Racking