Products

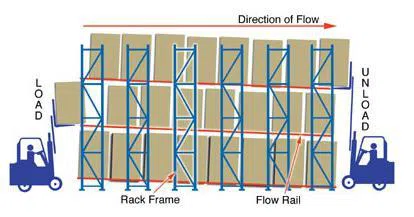

Gravity Racks For Pallets

Five Advantages Of Products

- Efficient product turnover

- Reduction in pick time

- Maximizes space available, allowing for increased pick location

- Maximizes space available, allowing for increased pick location

- As well as this, the added need for brake drums or break rollers allows you to maintain control of the pallet speed when moving across the rollers.

Product Details

Product Details

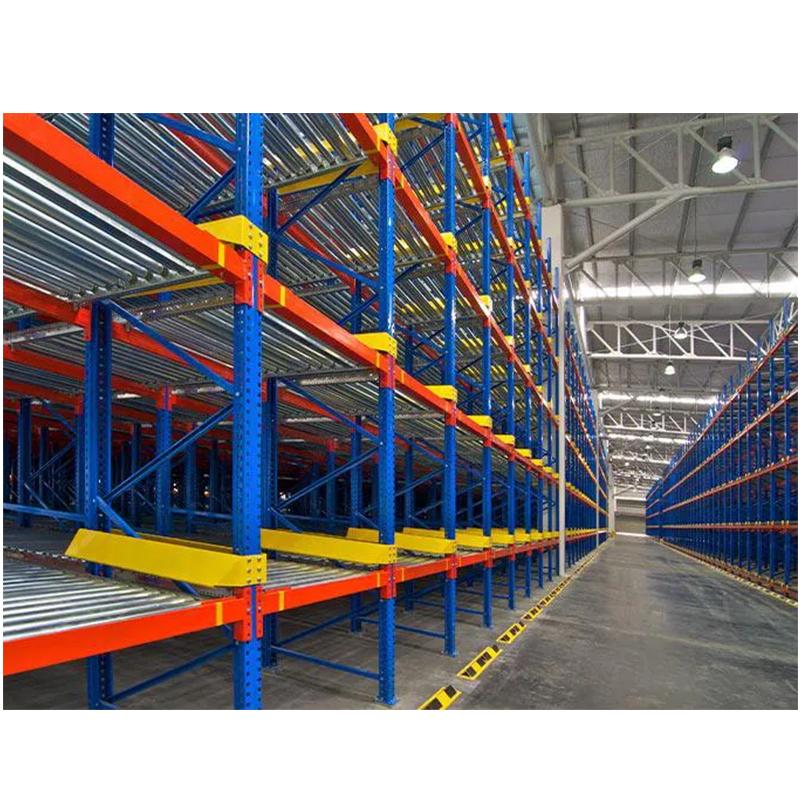

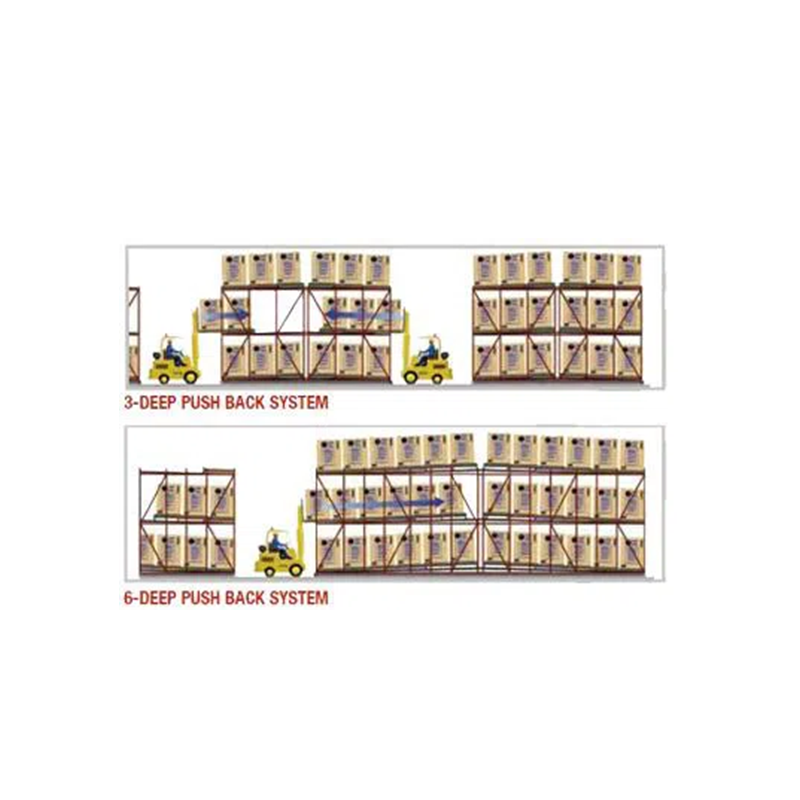

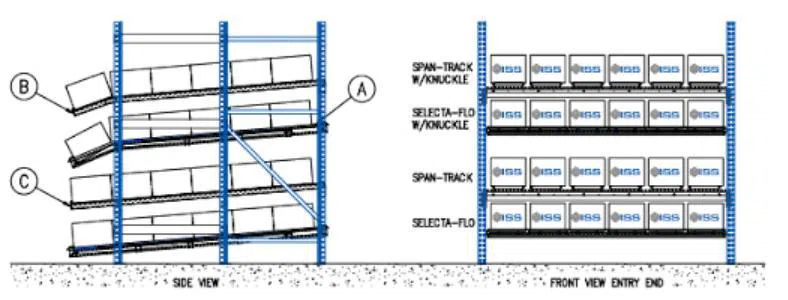

Gravity racks for pallets also known as gravity flow is a FIFO (first in, first out) dynamic storage system. Pallet flow rack makes it possible to achieve high density storage while maintaining FIFO retrieval order and handling efficiency. Gravity racks for pallets maximize storage space by minimizing aisles. Gravity pallet flow systems can be designed to hold up to 20 pallets deep in one lane, and allow for quick and efficient inventory turnover. Customization is the key in pallet flow rack systems, and manufacturers offer multiple types of rollers to meet the demands of individual users’ pallets and products. Some manufacturers can even customize their pallet flow racks with speed controller capacities that are uniquely designed for users’ product weight ranges.

Gravity racks for pallets provides deep lane storage and First in/First out (FIFO) pallet handling control. Its full roller pallet flow is an excellent way to accommodate different size pallets, heavy loads and beverage applications. The pitch of a pallet flow lane can vary from system to system. That being said, the most common pitch given to pallet flow lanes is 1/2” per linear foot. To illustrate this, imagine a pallet flow lane that is 20’ long. If the pitch is 1/2” per linear foot, the loading end of the lane will be 10” taller than picking end. This slant allows the pallet to “flow” effortlessly from one end of the system to the other.

Advantages

●Efficient product turnover

●Reduction in pick time

●Maximizes space available, allowing for increased pick location

●Manufactured from steel, all rollers roll independently, significantly increasing the flexibility and ease of handling for the picker.

●As well as this, the added need for brake drums or break rollers allows you to maintain control of the pallet speed when moving across the rollers.

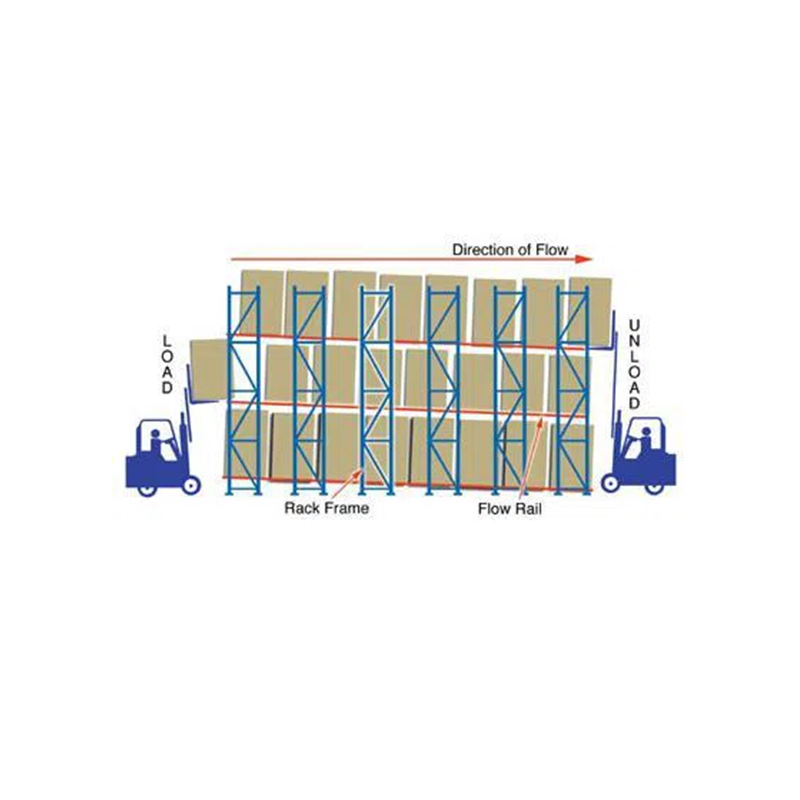

Operations

Gravity flow racks act as non-powered, downward-sloped storage conveyors, which allow for all subsequent pallets or cartons to move to the forefront, once the preceding item has been removed, otherwise known as first in first out (FIFO) racking.

Items are loaded into the high end of the rack, one by one. Within a confined lane, the product then travels forward over a deck of wheels or rollers, down the shelf, filling the structure from front to back end.

In utilizing gravitational forces, pallets and cartons naturally find their path, filing in an orderly fashion, while consistently refilling the forward-most position for easy retrieval.

Case

Jiangsu Welfor Storage Equipment Co., Ltd.

Contact Person: Casy Chen

Telephone: +86 13851406693

Landline: +86 025-52111679

Company Address: No.6 Tongkuang Road, Guli Industrial Development Zone, Jiangning District, Nanjing City, Jiangsu Province, China

Website: www.rackmanufacture.com

Previous: Gravity Flow Rack

Next: Gravity Racking System