Products

4 Deep Push Back Racking

Five Advantages Of Products

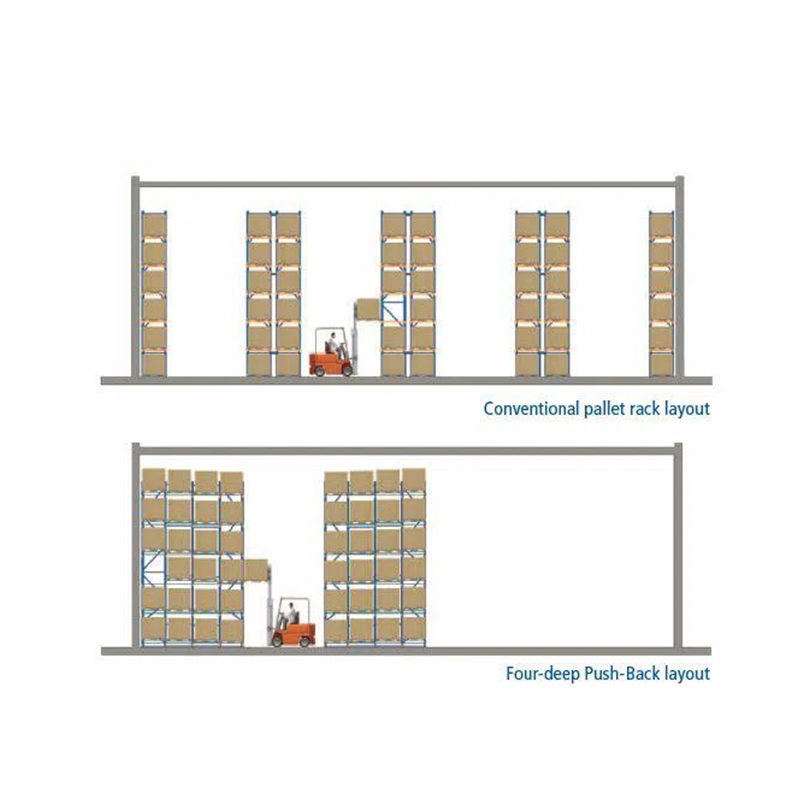

- Offer better use of available pallet space than most storage systems

- Minimizes honeycombing effect compared to drive-in rack systems

- Labor Savings – forklift drivers do not have to remove blocking pallets

- Enjoy more storage rack area with the single-aisle design

- Easy & fast loading and unloading of pallets

Product Details

Product Details

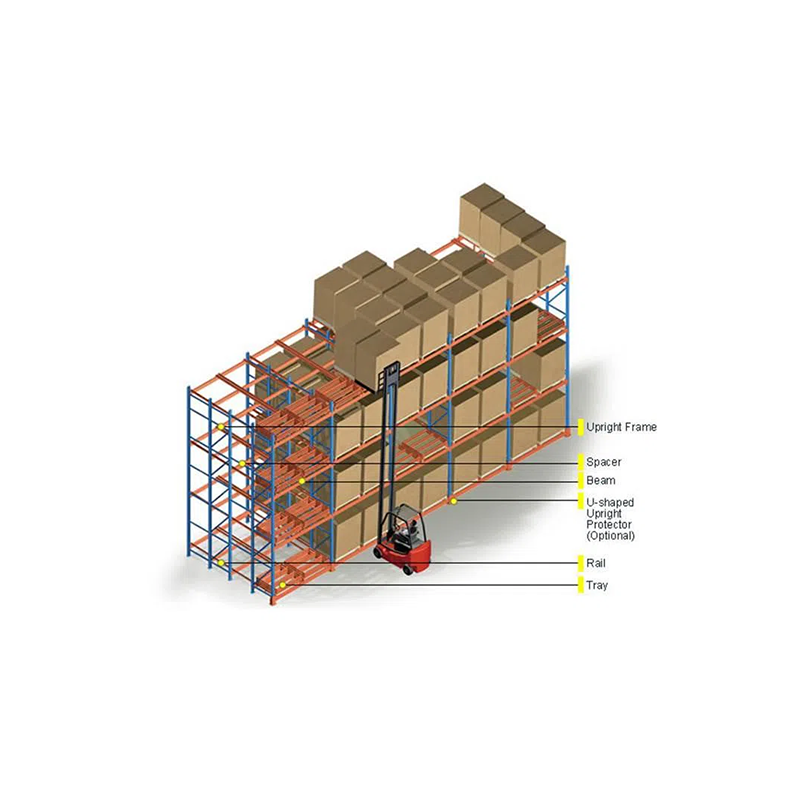

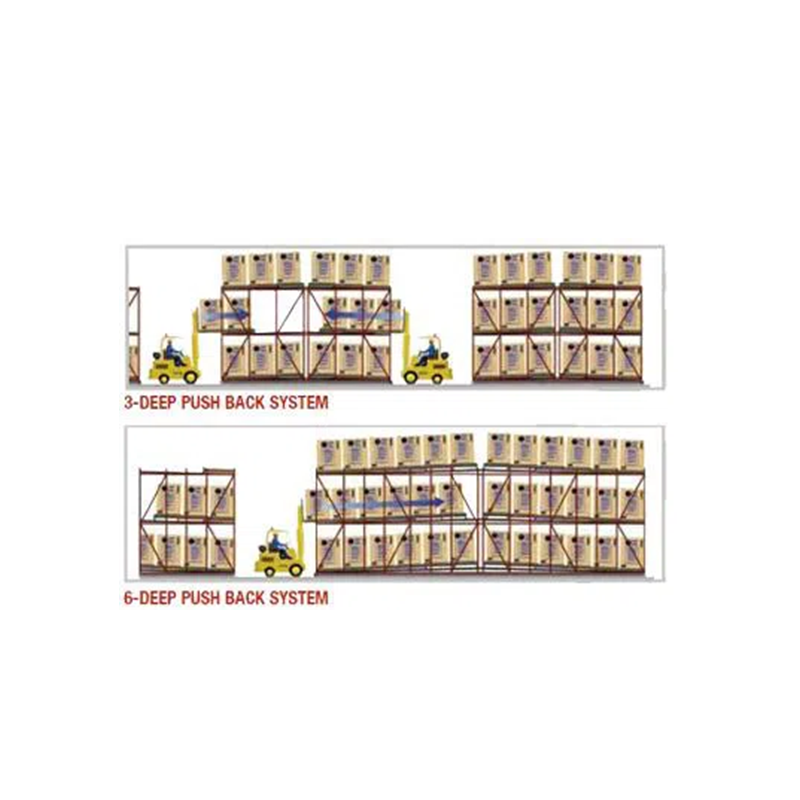

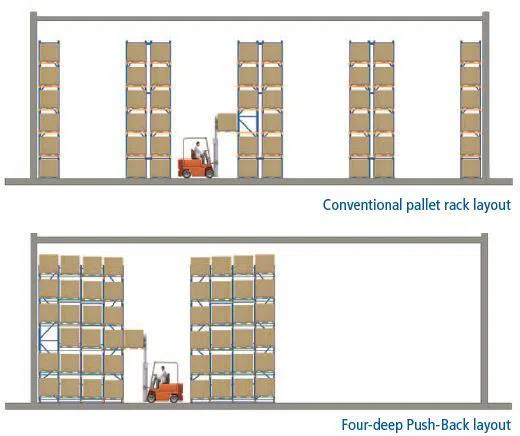

This system of pallet racking also uses gravity to push pallets in back to the front position during picking. Inventory is loaded onto pallets with nested carts that roll on slightly angled rails. Loading a pallet onto the racking system pushes the pallet behind it back one position. Unloading allows the pallet to roll forward smoothly and evenly.

Generally a higher-density storage option than standard selective pallet racking, the 4 deep push back racking is versatile, energy-efficient, and can be built several levels high and over 4 pallets deep. A few other pluses include easy access and last-in-first-out storage. You can also cut down on handling time as pallets and product move easily into place. This system provides the golden combination of density plus accessibility, which leads to higher productivity.

4 deep push back racking also evolves from pallet-style racks, also known as 4 deep push back racking. Using the principle of a combination of rails and pallet trolleys, the track has a certain gradient. Using the weight of the goods, because pallet goods are stipulated for single-end storage, and the goods are FILO (First-In-Last-Out), suitable for large batches and small varieties of goods. Storage, space utilization is high, and access is more flexible and convenient. The total depth of the shelves should not be too deep, generally within 4 Pallet depths, otherwise the space sacrifice will be greater due to the mutual insertion of the Pallet trolleys. The weight of single-carriage goods is generally within 1500kg, and the shelf height is generally less than 6m.

Advantages

●Offer better use of available pallet space than most storage systems

●Minimizes honeycombing effect compared to drive-in rack systems

●Labor Savings – forklift drivers do not have to remove blocking pallets

●Enjoy more storage rack area with the single-aisle design

●Easy & fast loading and unloading of pallets

●Each lane is LIFO, but FIFO can easily be achieved with proper design

●Large, coated wheels allow carts to roll smoothly

●Very low-maintenance, sealed bearing

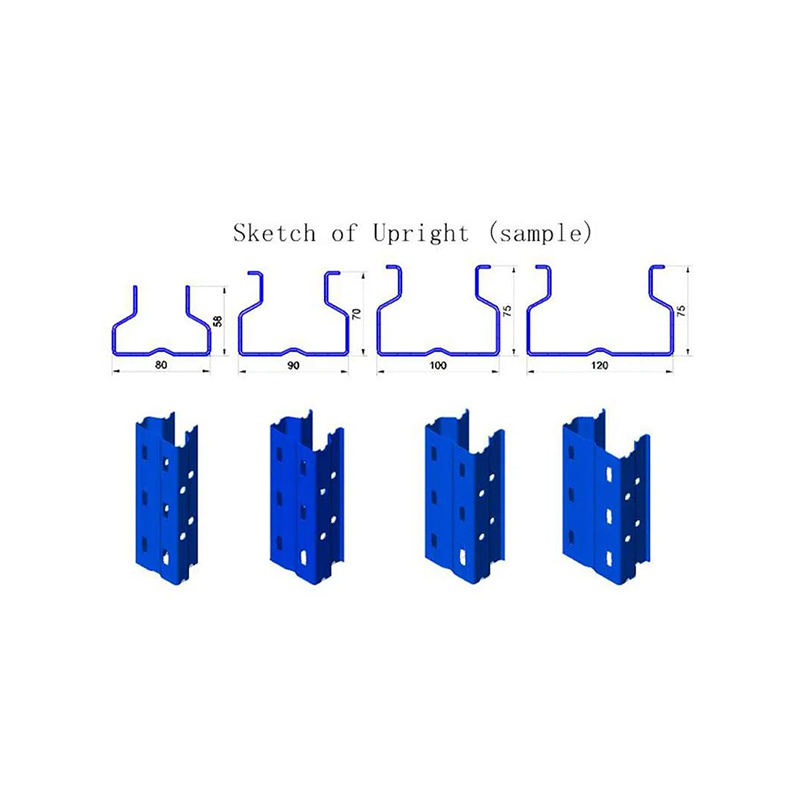

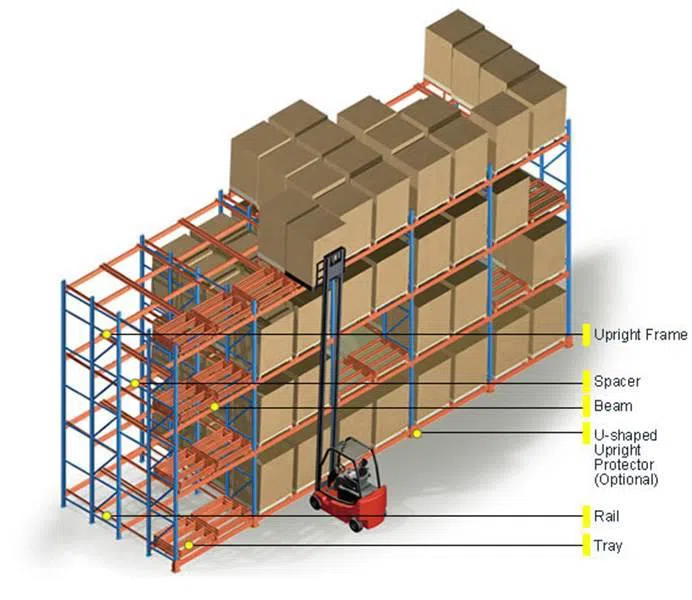

Structure

Operations

●When compared to usual rack, most forklift operators believe push back is an easier system to operate. It typically takes only 4 hours to become fully acquainted with the rack system.

●Because forklifts never enter a pushback system, damage to uprights is minimized.

●Pushback aisles usually only need to be 6″ wider than the manufacturer’s minimum aisle requirement.

●Push back requires little to no maintenance besides standard pallet rack safety checks.

●Pushback is compatible with counterbalance, reach, deep reach, swing reach, and even clamp forklift trucks.

●3000 pounds per pallet position is the standard design but they can be designed with a higher capacity.

●The most common pallet style in a push back system is the standard GMA but pushback can be manufactured for multiple styles of pallets.

●Typically push back will require an additional 6”-8”’s of height compared to standard selective.

●Pushback is often times used in combination with drive-in to maximize space.

●Unless noted, most push back rack systems in the US are designed with structural rack.

Case

Jiangsu Welfor Storage Equipment Co., Ltd.

Contact Person: Casy Chen

Telephone: +86 13851406693

Landline: +86 025-52111679

Company Address: No.6 Tongkuang Road, Guli Industrial Development Zone, Jiangning District, Nanjing City, Jiangsu Province, China

Website: www.rackmanufacture.com

Previous: Gravity Racking System

Next: Push Back Storage Rack