Products

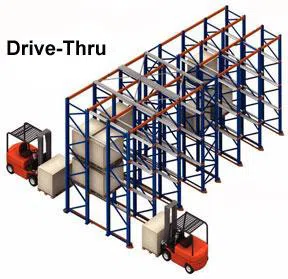

Cold Room Drive In Racking System

Five Advantages Of Products

- Moderate cost, high-density pallet storage.

- Uses common entry/exit into each bay of rack.

- Designed to store numerous pallets of the same SKU.

- Creates separation of pallet loads set in a bulk array, reducing damage.

- Increases storage height capability as compared to bulk stack storage.

Product Details

Product Details

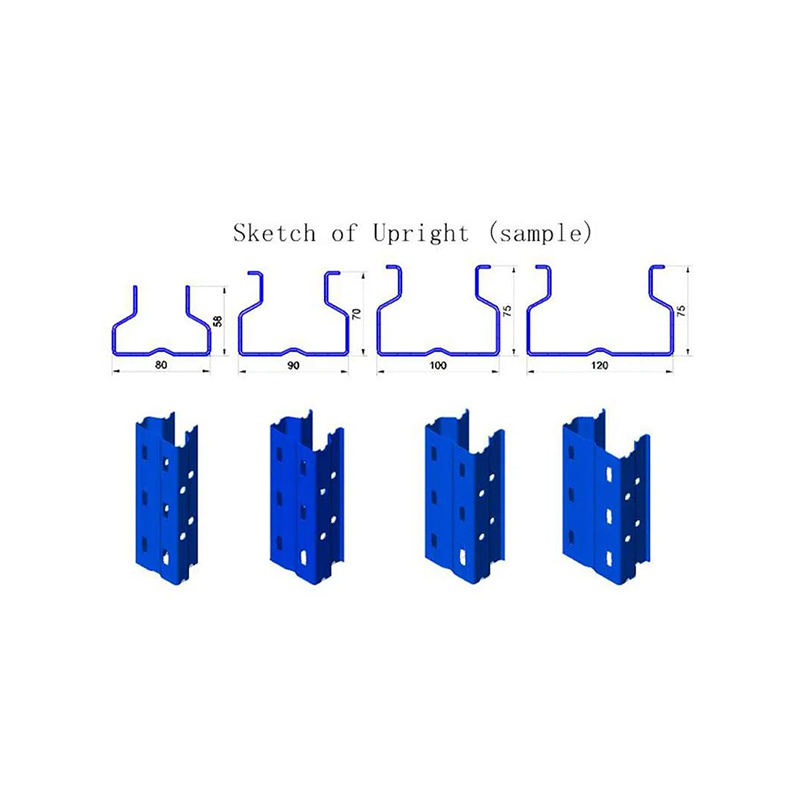

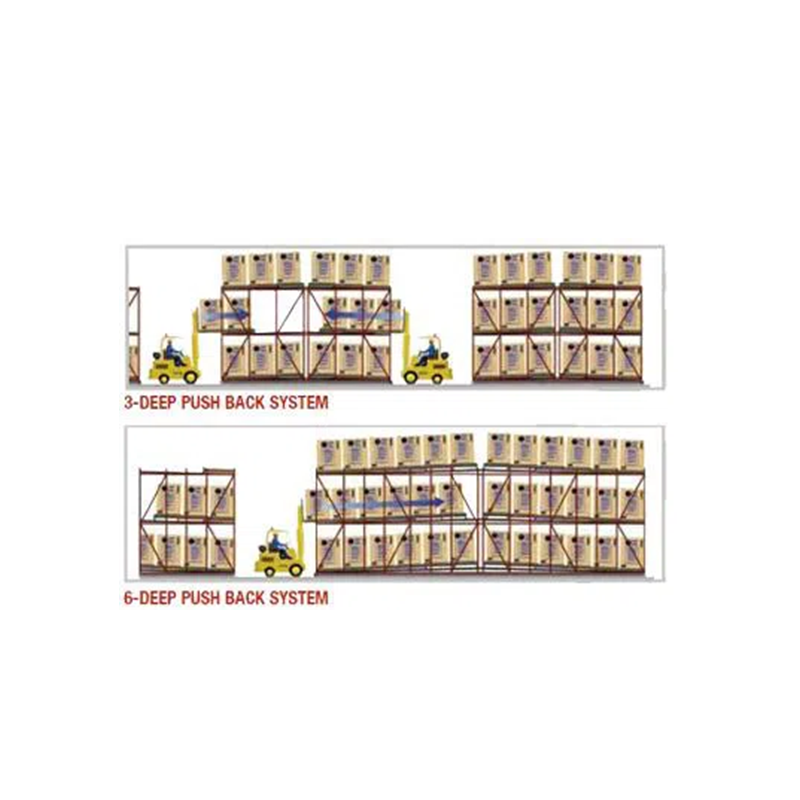

Cold room drive in racking system is installed in warehouses and distribution centers that need a cost effective, high density storage solution for their pallets and products. Because of its design, drive-in pallet rack is a first in, last out (FILO) storage system. Drive in racking is best used with a large quantity of like-products that are not time sensitive, in order to best utilize warehouse space. Warehouse access aisles are kept to a minimum with drive-in rack, often allowing users to achieve double or more storage capacity.

Cold room drive in racking system can be designed to store anywhere from 2 to 10 pallets deep per pallet position. If you’re curious about how a drive in rack system can help maximize your warehouse or distribution center space, contact one of our Minnesota-based pallet rack design specialists. We’re based in Minnesota, but have shipping points located across the country so you can take advantage of shipping savings.

Advantage

●Moderate cost, high-density pallet storage.

●Uses common entry/exit into each bay of rack.

●Designed to store numerous pallets of the same SKU.

●Creates separation of pallet loads set in a bulk array, reducing damage.

●Loading and maintenance

Safe loading of all types of Cold room drive in racking system is necessary in order to protect your personnel, your product, and your racking. With forklifts entering and exiting the rack system, the importance of being attentive to safety when loading pallets in drive-in systems can’t be overstated. Operators should enter the system slowly and deliberately, and should carefully avoid hitting the system’s upright frames. Prior to system use, it should be verified that the forklift that will be used is compatible with the rack system’s dimensions.

Safe unloading of drive-in pallet rack is similar to safe loading. Drive-in rack systems can be quite deep, and forklift operators must take great care when reversing out of the system. While speed is important in most operations, safety always takes priority, and colliding with an upright frame while underneath a system is unsafe by any measure.

Because forklift operators are driving inside the rack system itself, it’s extremely important to ensure drive-in pallet rack systems remain in stable condition. While drive-in rack systems generally require very little maintenance, it’s highly recommended to perform regular safety checks to confirm that no damage has been done that could compromise structural integrity or operator safety. When performing the check, focus on checking for damaged frames, loose anchors, and damaged pallet rails.

Case

Jiangsu Welfor Storage Equipment Co., Ltd.

Contact Person: Casy Chen

Telephone: +86 13851406693

Landline: +86 025-52111679

Company Address: No.6 Tongkuang Road, Guli Industrial Development Zone, Jiangning District, Nanjing City, Jiangsu Province, China

Website: www.rackmanufacture.com

Previous: Drive Thru Racking